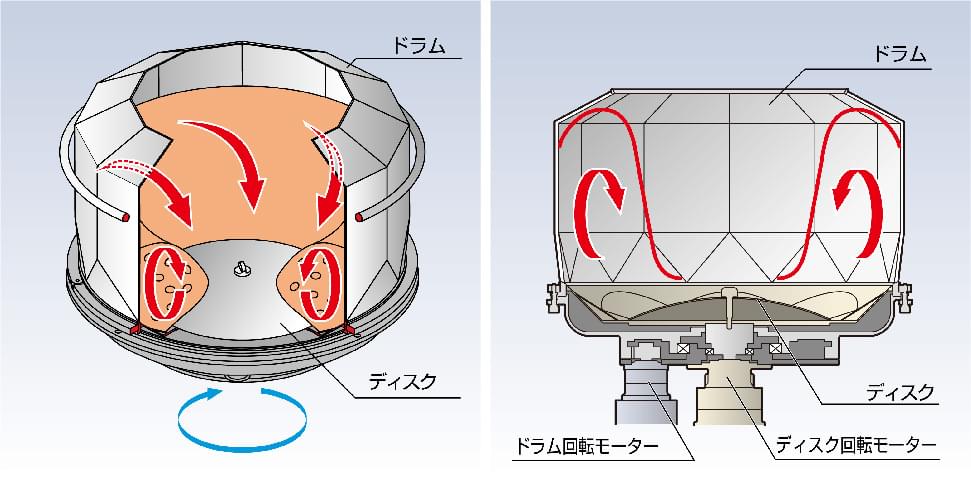

Centers to be coated will first roll and then are transferred to the disc’s outside due to the centrifugal force caused by high speed rotation, and will rise along the inner side of the drum. The centers which reached to the maximum height will roll and disperse over the wide surface area to return to the center part of the disc. Cycle of this centers’ movement create vortex flow.

Conventional revolving pans tend to create rotational flow only on the surface of the lump of centers. On the other hands, centrifugal coating machine constantly creates rotational flow in three-dimension, so that coating materials will be widely spread and each center will be rapidly coated.

Coating machines were developed by taking a hint from the operating principle of flow in mass finishing machines and switching the technology of "grinding" over to the technology of "attaching."

The revolving pan process that is currently used for granulation and coating process in food (confectionary) industries has been used for a long time and its structure is very simple. On the other hand, use of the pan requires experience and skill. It is often heard that the appearance of coating varies depending upon the quality of workers. More recently, there have emerged problems of aged workers, unfavorable working environments and low job settlement ratio of young workers due to heavy workloads, which cannot be ignored. In addition to this, the recognition of food safety have been heightened and the introduction of Hazard Analysis-Critical Control Point(HACCP)and ISO have started to become established. We, at Tipton, have developed and started offering a coating machine that can remove or alleviate these problems and that will help revolutionize manufacturing of food products.

Operating Principle and Structure of Multi Spin Coating Machines

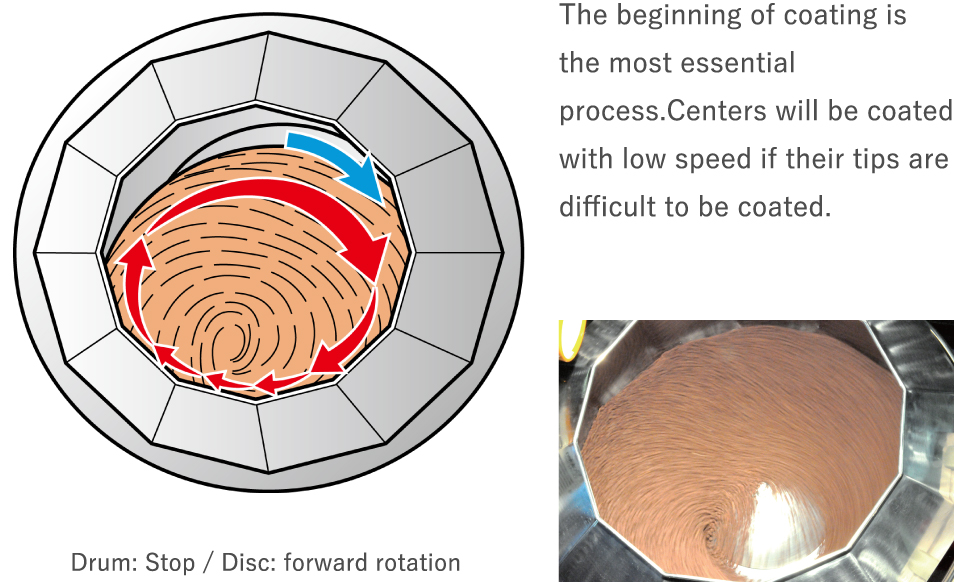

How To Use

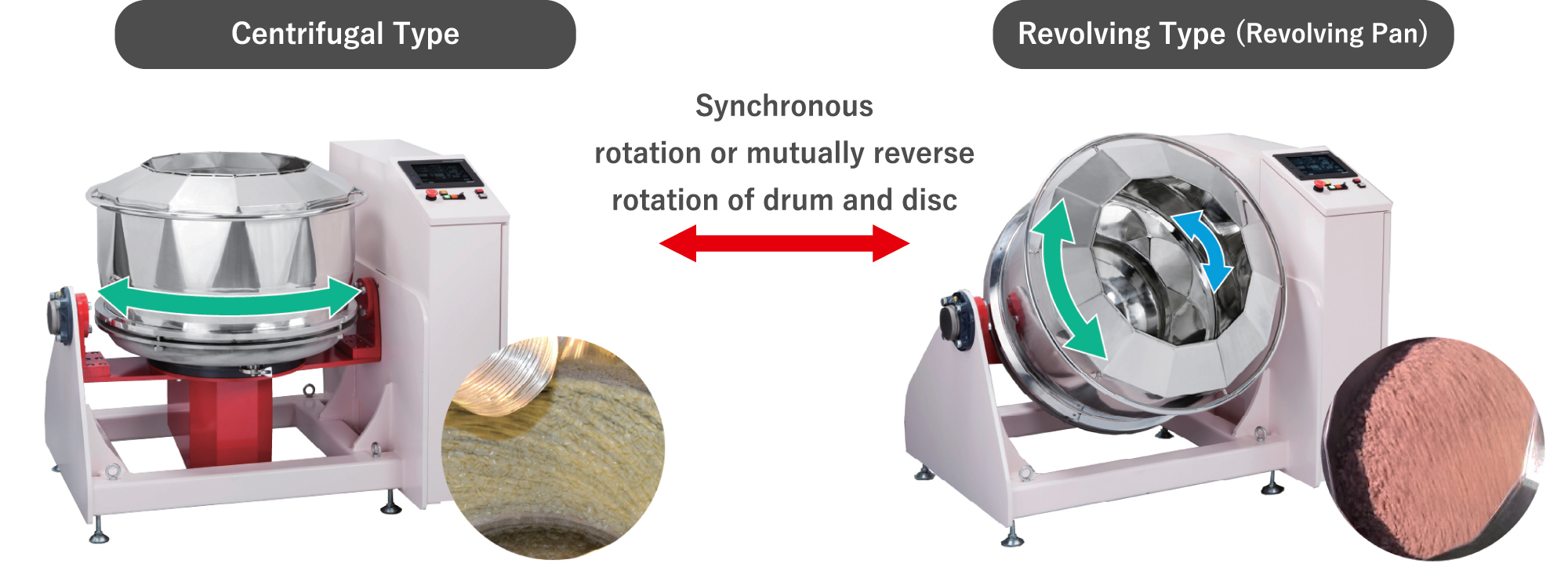

Using Horizontal Movement

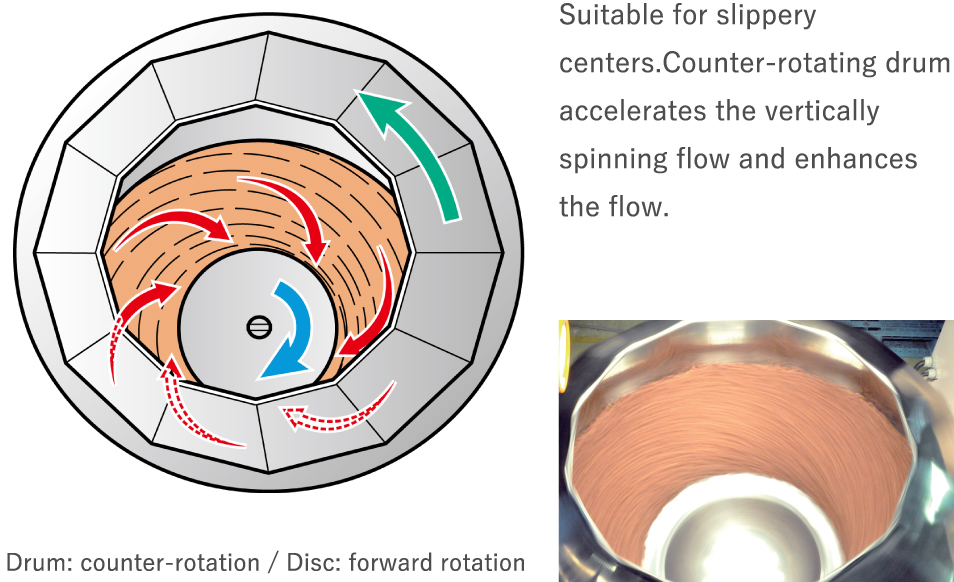

By rotating the disc with high speed, vortex flow is created. When rotating the drum reversely, vertical spinning flow will be enhanced and will be suitable for slippery centers. Coating is completed in a short time using centrifugal force.

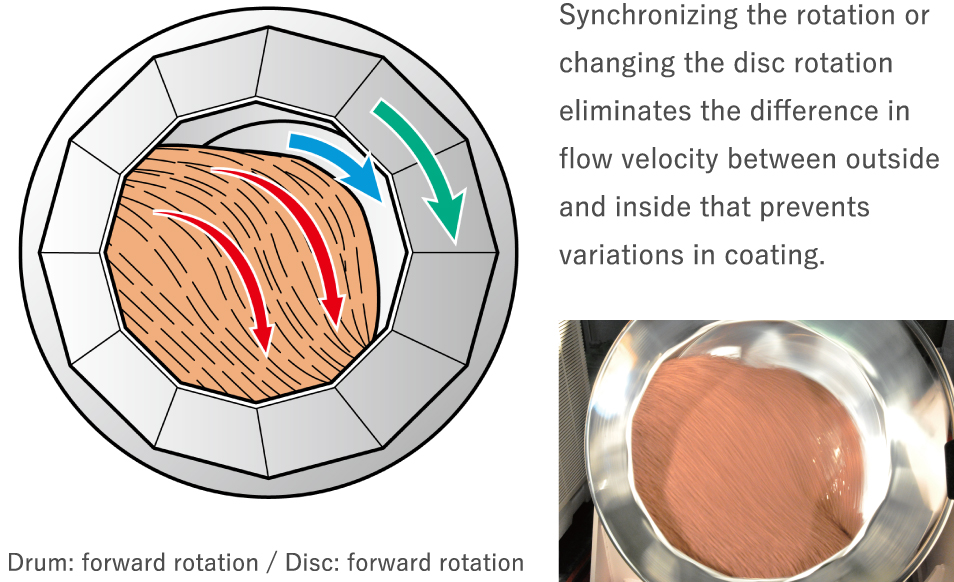

Using Tilted Movement

Synchronous rotation of drum with disc allows revolving pan’s function. Longitudinal direction of the flow can be controlled by changing the disc rotation. Constant and uniform quality is ensured.

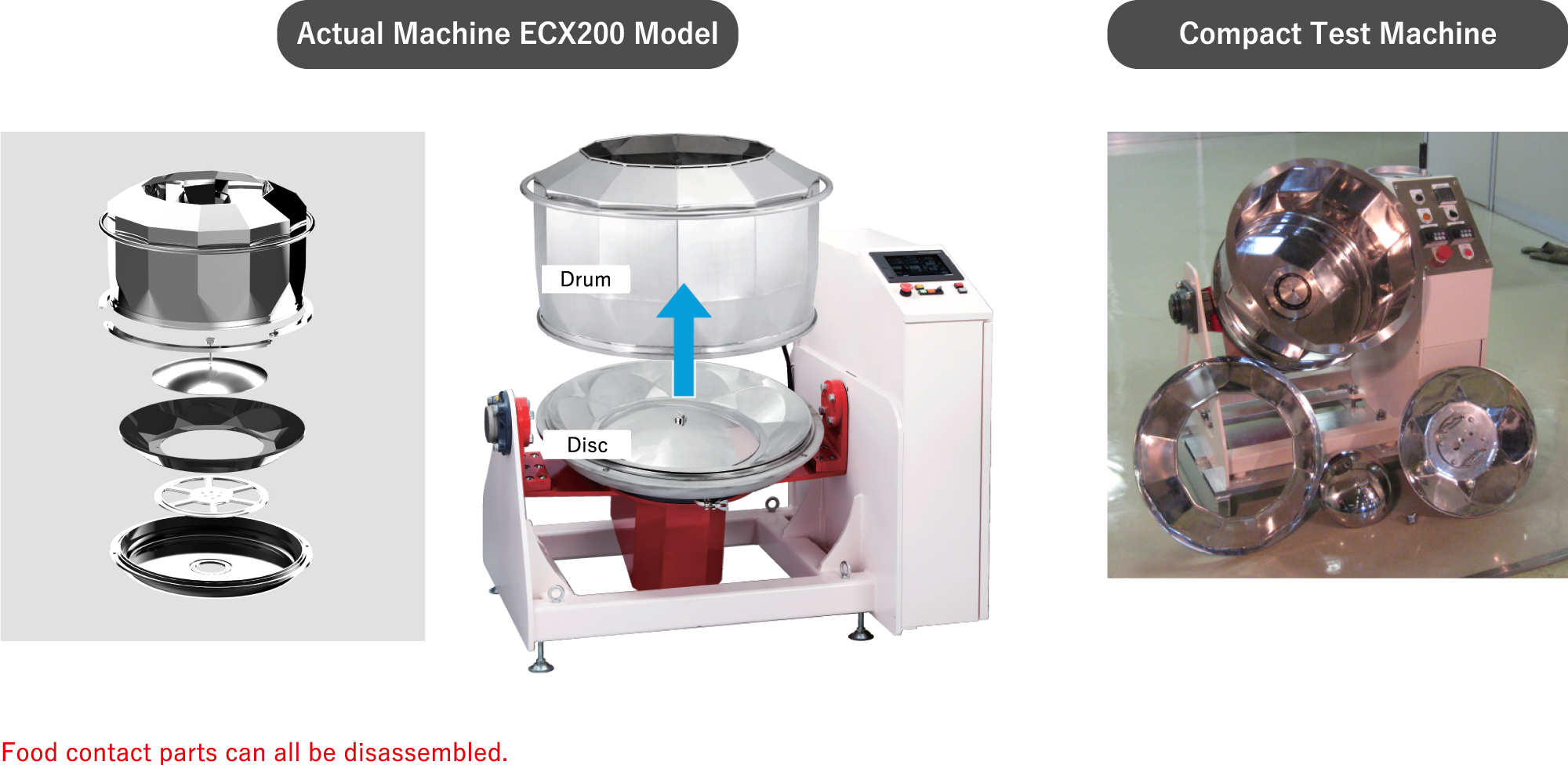

Exposed View When Cleaning

Flow Structure of Multib Spin Coating Machine

-

Centrifugal Mode (Horizontal)

-

Centrifugal Mode (Slope)

-

Revolving Pan Mode (Slope)

-

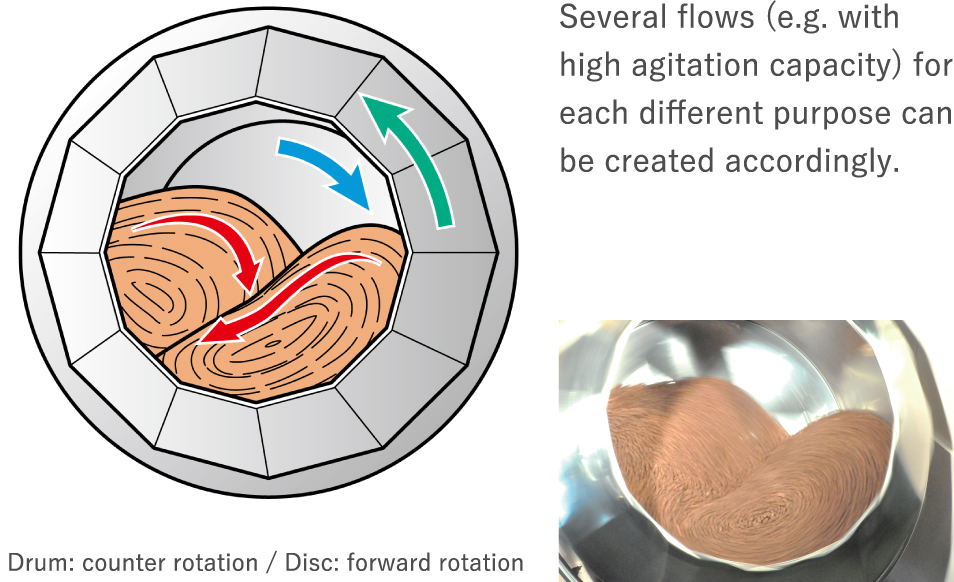

Agitating Mode (Slope)

Tumbling fluidizing including these

flows can be mutually and continuously created.