A Leading Share in a Niche Market

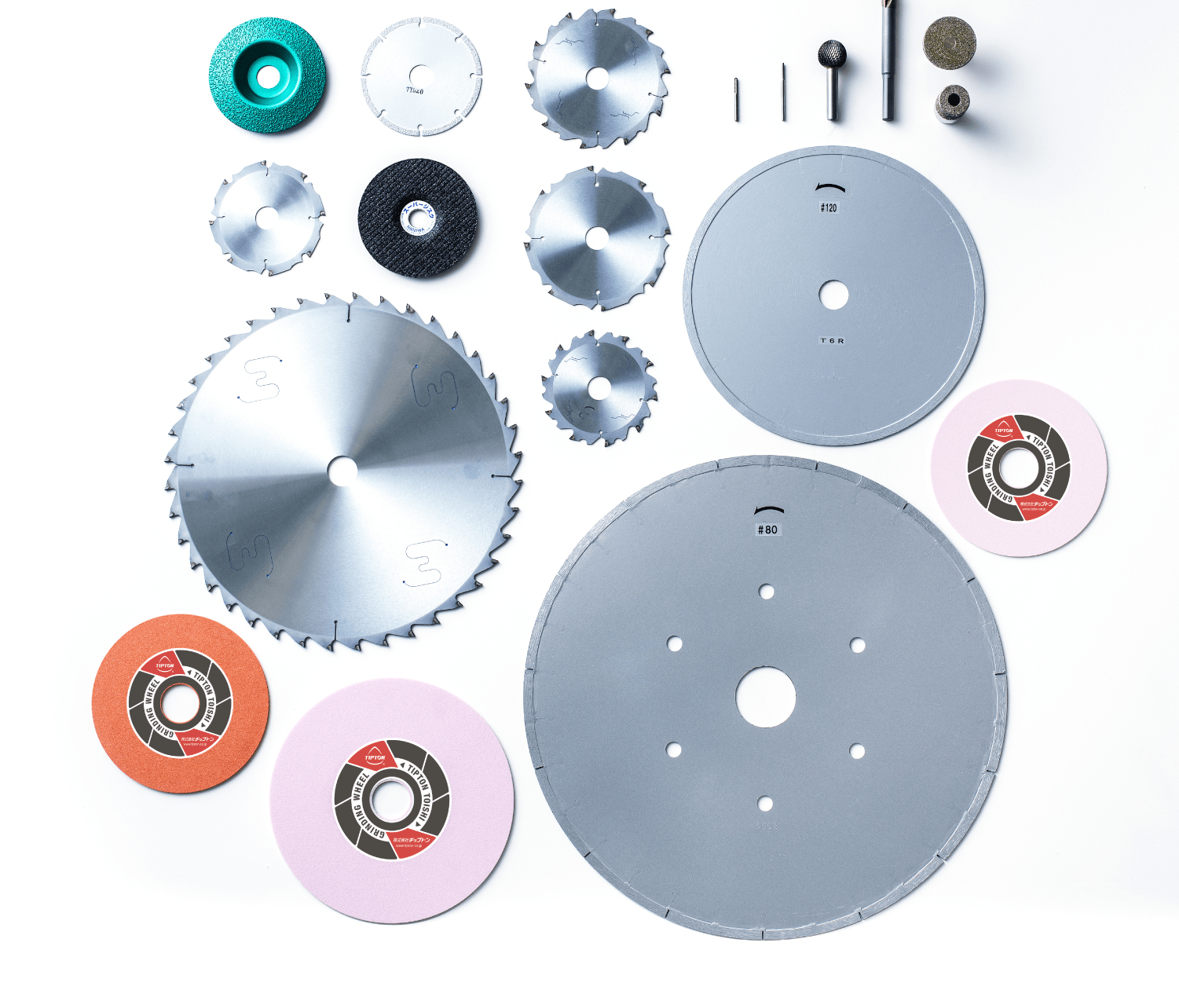

Tipton's grinding wheels have been widely used for 40 years in tile adhesion and cutting tool polishing. Recently, we have been expanding applications to meet customers' expectations in the siding process, building stone process, concrete secondary product process, quartz stone process, artificial marble process, fiber reinforced cement board process, and melamine facing plate process of the construction materials industry.

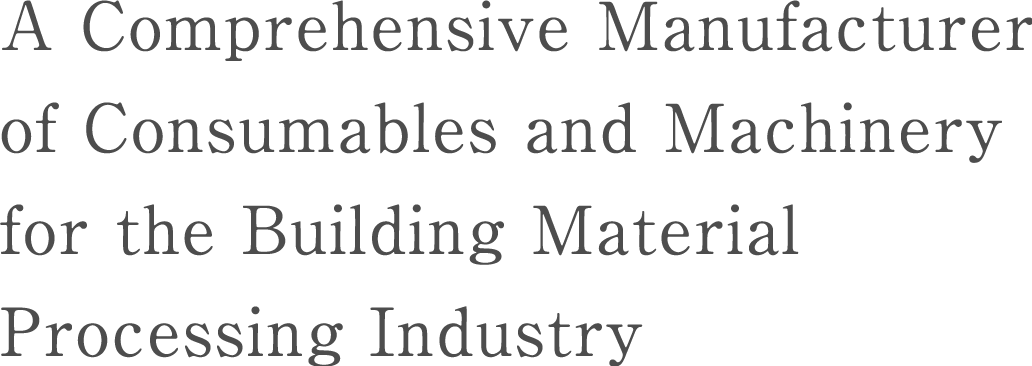

Tile Processing

As a result of diversifying design in modern architecture, the role of tile accessories (L-shaped tiles), in particular, tiles that are attached by bonding has increased. Tipton has been supplying grinding wheels, diamond cutters, adhesives, other consumables and cutting machines to customers in the bonding industry over the past 50 years.

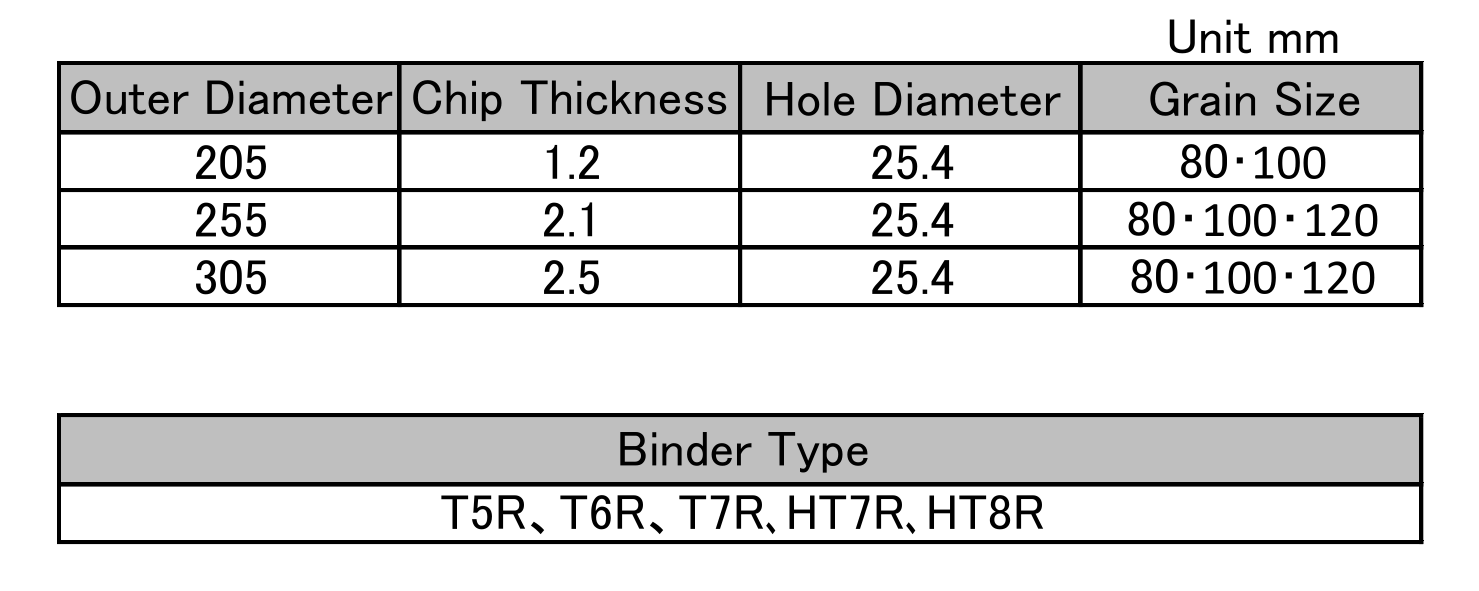

Siding Processing

Just like tiles, the sides that make up the outer walls of general housing come in assorted designs (natural stone, bricks, tile-look materials). Projected corner materials are used as the building material for corners, and the role of these materials is increasing more and more. In recent years, Tipton has put its know-how in tile processing to good use, has made proposals for chamfering processing that uses dry finishing and has achieved results in this area.

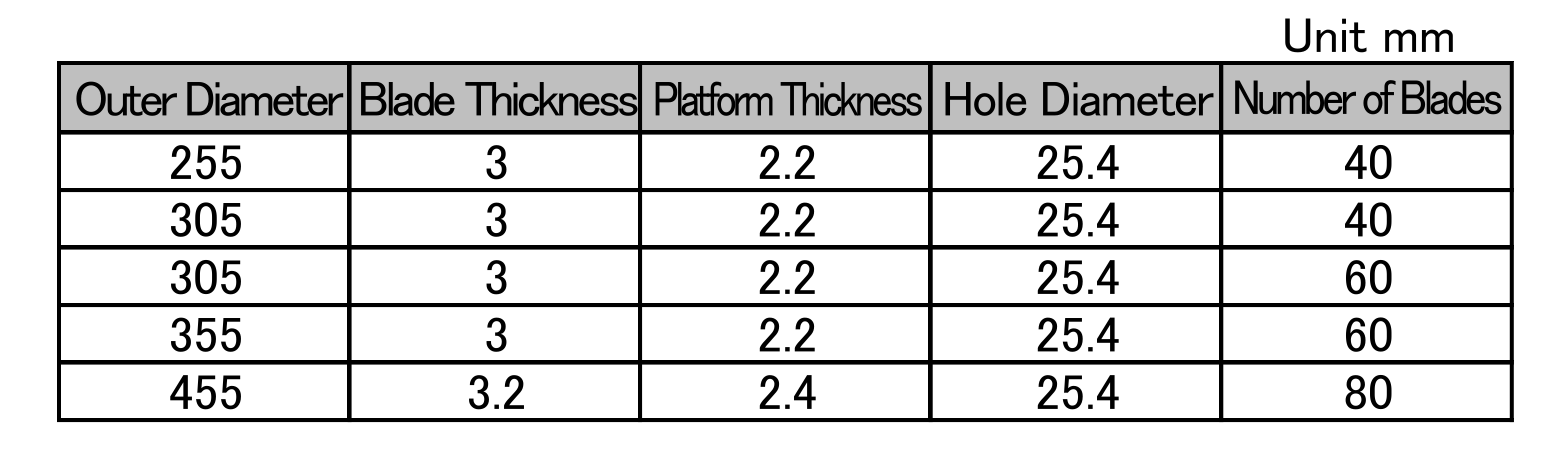

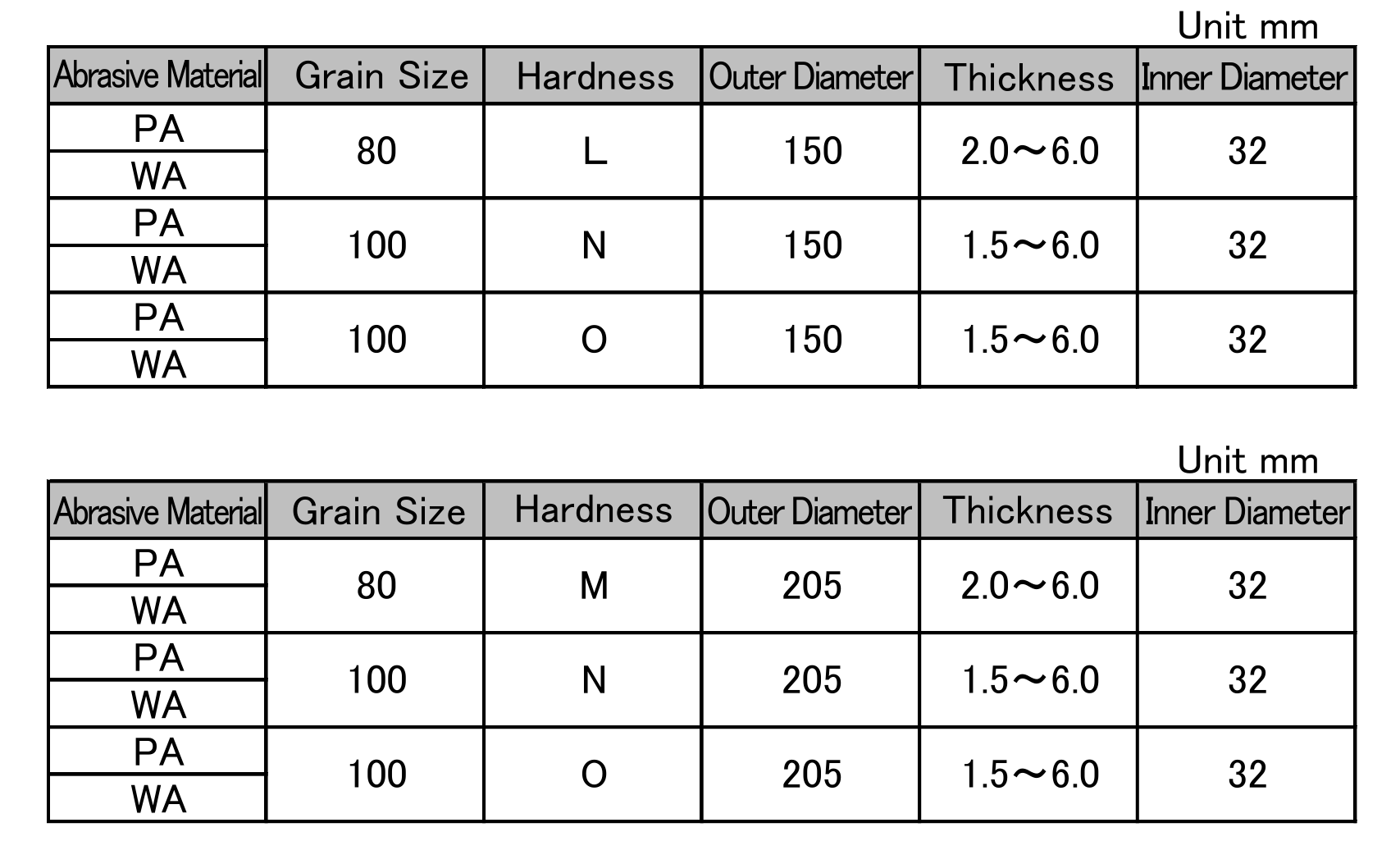

Cutting Tool Polishing

Our vitrified thin grinding wheels and CBN grinding wheels are used in the polishing of metal saws for cutting thin metal. Our dealings with this industry stretch back for more than 50 years. Our diamond grinding wheels are also used in the polishing of diamond tip saws.