History

| Year | Organization | Consumables Development | Machine Development | |

|---|---|---|---|---|

| Mass Finishing Machine | Another Equipment | |||

| 1939 | Dainippon Seito K.K. was founded In Minami-ku, Nagoya. |

Grinding Wheels were developed |

||

| 1953 | R&D into Mass Finishing was started |

|||

| 1955 | Rotary Barrel Finishing Machine was developed |

|||

| 1956 | Certified as a JIS factory (No. 4879) of manufacturing the entire range of vitrified products. |

|||

| 1957 | Abrasive Media (patent applications) were developed |

R&D into Mass Finishing was started |

||

| 1959 | K.K. Shikishima Tipton Kenmaseki established as a company specializing in mass finishing. |

Triangular Original Cut Press Abrasive Media was developed |

||

| 1961 | Centrifugal Barrel Finishing Machine was developed |

|||

| 1963 | K.K. Shikishima Machine as a factory specialized to finishing machines was established. |

Recipro Finishing Machine was developed |

||

| 1966 | K.K. Shikishima MUL-BII as a company selling catalyst carriers was established. |

Inert Balls for the Oil Refining and Petrochemical Industries were developed |

||

| 1970 | Multiplex-multistage Vibratory Barrel Finishing Machine was developed |

|||

| 1972 | K.K. Tack as a company specialized to automatic finishing system was established. |

|||

| 1973 | K.K. Tipton Espo as a comprehensive sales company of mass finishing machine was established. |

Irregular Shape and Micro-Finishing 3P Abrasive Media was developed |

||

| 1977 | Unmanned Gyro Finishing Machine was developed |

|||

| 1984 | Fully automatic centrifugal barrel finishing machine HS-200FA model was developed |

|||

| 1985 | Mechatronic Pavilion (mass finishing unmanned model factory) was opened to the public |

|||

| 1987 | K.K. Twinne was established. |

Fully automatic Heavy Hybrid Barrel Finishing Machine was developed |

||

| 1992 | High-precision Brushing Machine, Standard Brushing Machine Parthenon were developed |

|||

| 1993 | 8 Tipton Group companies were merged to Tipton Corp. |

Environmentally Friendly ECO Compound was developed |

Dry Type Centrifugal Disc Finishing Machine was developed |

Candy Coating Machine CCM was developed |

| 1994 | Tipton US Corp was established in U.S.A. |

|||

| 1995 | Vibratory Conveyance Type Demagnetized Separator Under 5 NS-400 model was developed |

|||

| 2000 | Dry Type Centrifugal Barrel Finishing Machine was developed |

Food Coating Machine ECM model was developed |

||

| 2002 | Integrated Nagoya Factory and Yokkaichi Factory to form Tobishima Factory newly constructed. |

|||

| 2004 | Acquired ISO 9001 certification. |

|||

| 2005 | Centrifugal Disc Finishing, Clearance Zero was developed |

|||

| 2006 | Acquired ISO 14001 certification. |

|||

| 2008 | New type Centrifugal Barrel Finishing Machine was developed |

|||

| 2010 | Business category of Tipton US Corp. was changed to Tipton Ceram Corp. |

|||

| 2012 | Raschig Ring for the petrochemical industry was developed |

Mighty Mild Hi-gravitational Barrel Finishing Machine was developed |

||

| 2013 | Coating Machine ECX Model was developed |

|||

| 2017 | Mighty Mild Design Machine was developed |

|||

| 2018 | Taylor Vortex Flow Nano Reactor |

|||

| 2024 | Establishment of a lab room and office in Detroit, USA |

|||

-

View of Dainippon Seito K.K. headquarters at the time of its founding -

Centrifugal Barrel Finishing Machine HS-6000 Type -

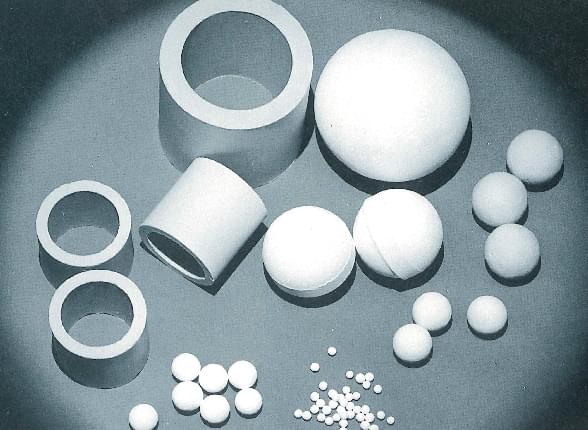

Ceramic Inert Ball for the Oil Refining and Petrochemical Industries -

In 1953, the 19 buildings of the Main Factory were restored and rebuilt, and operation was started -

Multiplex-Multistage Vibratory Barrel Finishing Machine CWS Type. -

Food Coating Machine ECM model was developed -

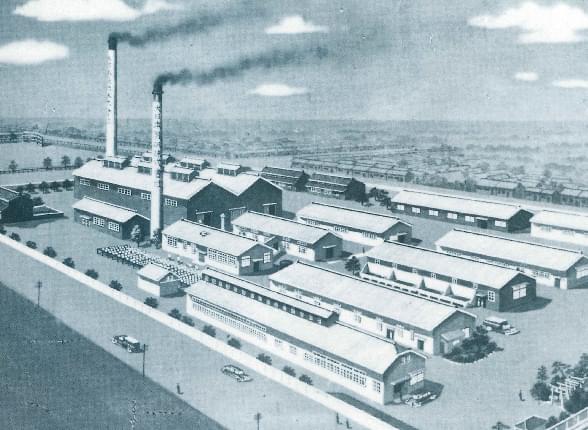

Tobishima Factory -

Mighty Mild was designed. -

Taylor Vortex Flow Nano Reactor