Operating Principle of Taylor Vortex Flow

This is the flow of a fluid that regularly forms a ring pair vortex in both the inner and outer cylinder spaces as a result of rotating a cylinder inside a cylinder on the outside that is fixed in place.

Taylor Vortex Flow

This innovative mixer/dispersing/reaction machine has no "fins."

Immediately after operation is started, an overall uniform Taylor vortex flow is formed so that the overall mass is mixed and reacts.

The number of rotation and gap ratio can be changed to match the required reaction characteristics.

Benefits of the TVF Model

- Uniform mixing of liquids is possible

- High-purity particles can be produced

- Mixing of nano-structures also is possible

- Continuous manufacturing is possible

- Mixing time can be shortened

- Strong (large) shearing force several times that of screw type stirring

- As structure and operating principle are simple, transition from laboratory test equipment → pilot test equipment → plant mass-production machine is easy(compatibility between these applications is high)

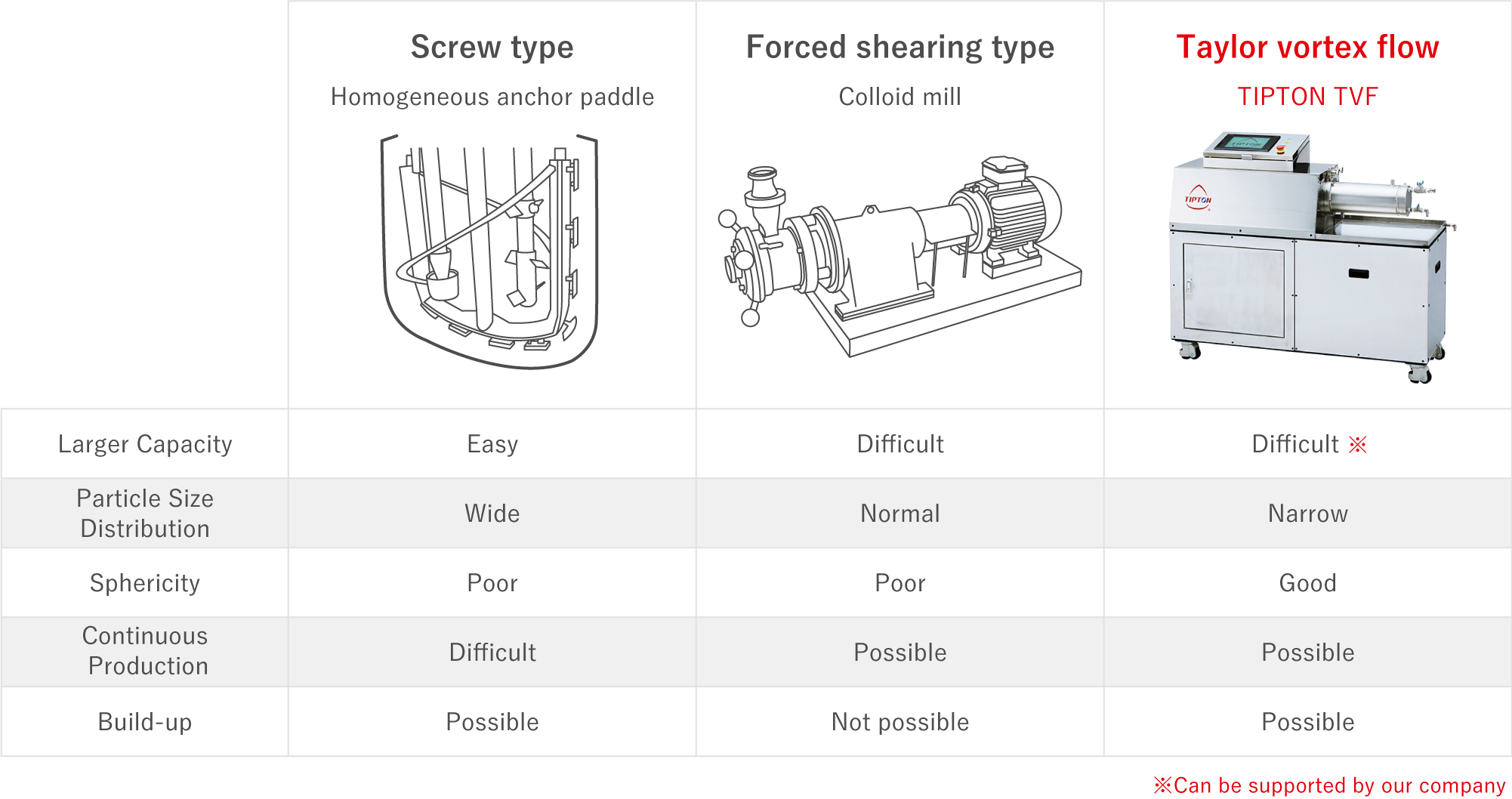

Comparison of Other Mixer/Dispersing Machines

Differences with Stirring and Reaction Machines on the Market

Compared with existing screw type stirring and reaction machines, on the microflow reactor Taylor Vortex Flow that makes use of Taylor vortex flow, shearing force is at least six times higher, and the cooling and warming effect is high which results in a faster reaction. In addition, this machine has a dual advantage that it processes continuously and can be downsized. Also, little time is needed for cleaning and switching over to new tasks.