We will exhibit our coating technology at「ALL PACK INDONESIA」

Date:October 9 (Wed) – 12 (Sat)

Venue:Jakarta International Expo (JIExpo), inside FOOMA Pavilion

Booth:DF007

For more information, click on the following link ALL PACK INDONESIA

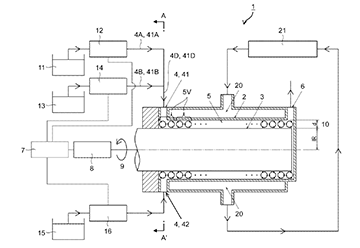

We will be exhibiting the multi-spin type coating machine “ECX” in the FOOMA pavilion, which is expected to reduce time, material loss, and save on labor. By processing using the vortex flow as formed characteristically by ECX’s multi-spin mechanism, it is possible to process quickly and uniformly. Our products are used by many customers both domestically and internationally including major confectionery manufacturers – chocolate coating, bean confections, gummies, etc.

We look forward to seeing you there.