We will exhibit our coating technology at「Fi Asia Indonesia Jakarta」

Date:September 4 (Wed) – 6 (Fri) 2024

Venue:Jakarta International Expo (JIExpo), PT. HALIM SAKTI PRATAMA Co. booth

Booth:B2G08

For more information, click on the following link Asia Indonesia Jakarta

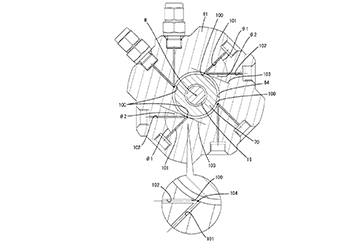

Tipton will be exhibiting our multi-spin type coating equipment “ECX”, which aims to reduce time, material loss, and save on labor at a booth organized by PT. HALIM SAKTI PRATAMA. By processing in a vortex flow environment formed characteristically with our multi-spin mechanism, it is possible to process quickly and uniformly as a result. Our products are used by many customers both domestically and internationally including major confectionery manufacturers for coating chocolates, confectionaries, gummies, etc.

We look forward to seeing you there.

-360x248a-360x248.png)