Contract Analysis Service Wins Award at Nagoya Industrial Technology Grand Prix 2025

Our contract analysis service for barrel polishing has won the “Director of Nagoya Municipal Industrial Research Institute Award” at the Nagoya Industrial Technology Grand Prix 2025, hosted by the Nagoya Industrial Promotion Corporation.

The Nagoya Industrial Technology Grand Prix honors innovative technologies and new products developed by small and medium-sized enterprises in Nagoya and the surrounding region.

The award ceremony will be held on February 20, 2025, at the Nagoya Municipal Industrial Research Institute.

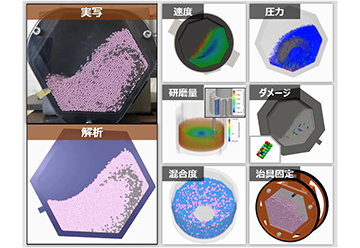

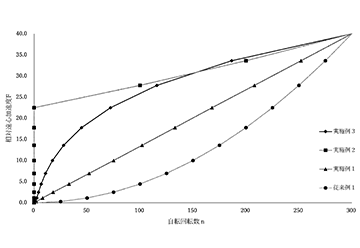

Our barrel polishing contract analysis service uses a proprietary simulation system developed in-house to analyze the polishing process in detail.

By accurately simulating the behavior of workpieces and media, the service enables customers to optimize processing conditions, improve product quality, and reduce trial-and-error costs.

Nagoya City press release Click here >

-360x248a-360x248.png)