Duration : 5 – 11 October 2024

Venue : Tokyo Big Sight

Booth No. : W4046 ( West 4 Hall)

For more information : JIMTOF 2024

At this exhibition, we will display our latest barrel finishing machines and abrasive media, combined with our commissioned analysis service for barrel simulation.

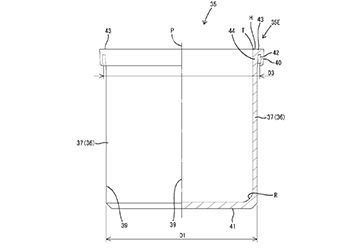

Our Mighty Mild polishing machine’s patented “low-speed, high-pressure flow” technology be able to reduce process time by 70%, cut abrasive stone wear in half, and also reduce dents and chips on workpieces by up to 80%.

“Drag-Finish” polishing machine has double speed of conventional machines and a wide range of work holding angle settings, which allows even long workpieces can be processed in a short time. The keyless chuck helps shorten setup time. Ideal for grinding tools and artificial bones.

For abrasive media, “Precision Micro E Series” which are designed to hit the inner corner without clogging even on complicated shapes, Plastic media “SAC” which enables mirror finish, SMD” for tools and other cemented carbide materials will be exhibited as well.

Our simulation services help clarify the issues facing your barrel process by quantifying flow velocities and impact forces.

We are looking forward to seeing you at our booth.

Click here for booth info page

Click here for Mighty Mild video

Click here for Mighty Mild Vertical video

Click here for Drag Finish video

Click here for E-series media video

Click here for SAC video

Click here for SMD video

Click here for Simulation service video

-360x248a-360x248.png)