We have published a patent concerning crack-resistant polishing for Mighty・Mild®.

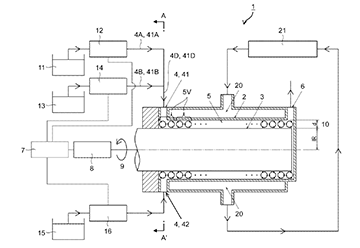

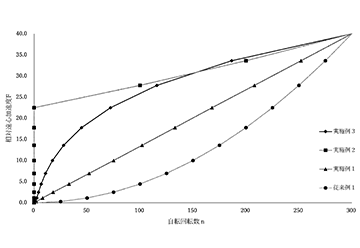

We have published an international patent application for a control method that dramatically reduces chipping and impact marks on workpieces occurring during the acceleration phase of initial polishing in heavy-pressure barrel polishing machines/Mighty・Mild®.The invention, jointly developed by Kanazawa University and Tipton Corp., is titled “Rotational Speed Control Method for Centrifugal Barrel Polishing and Centrifugal Barrel Polishing Method” (Publication No. WO/2025/177749).

-360x248a-360x248.png)